Pumping Stations

-

-

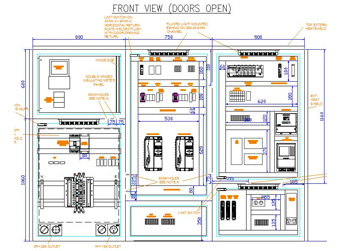

Curtis St Pump Station

Technologies: Switchboard Design, Telemetry

-

In conjunction with LCG Electrical. Custom designed switchboard enclosure for a roadside pumping station, incorporating features to ensure maximum lifespan in the harsh outdoor conditions – including IP66 fully welded construction, external heat shields on all sun affected surfaces.

-

-

-

-

Flagstone Treatment Plant Upgrade

Technologies: Pump Control, Reverse Engineering, Project Management

-

Regular faults and maintenance issues prompted the customer to seek a better solution for the controls of their outdoor waste water pumping/treatment filters at the Flagstone Treatment plant. In conjunction with T2 Electrical & Data, we put together a proposal for moving all of the pump controls into an enclosed air conditioned shed. This involved reverse engineering the design of the pump controls, to determine how many underground multi-core cables would be required for the relocation. The upgrade also had to be completed with maximum of 4 hours downtime. Careful planning and extensive pre-work enabled this goal to be achieved.

-

-

-

In conjunction with LCG Electrical. Custom designed switchboard enclosure for a roadside pumping station, incorporating features to ensure maximum lifespan in the harsh outdoor conditions – including IP66 fully welded construction, external heat shields on all sun affected surfaces.

-

-

-

Suspended Solids Analyzers Loganholme Waster Water Treatment Plant

Technologies: Field Sensors, Project Management

In conjunction with T2 Electrical, Integrelec was required to propose a solution for adding five new suspended solids analyzer probes at various remote points around the site. Existing conduits were full or un-available, so it was looking like the cost would be very great to run new trenches and cables over 300m back to the control rooms. However, upon close inspection we determined that a creative technique could be used to combine the new sensor signals onto existing cables from existing sensors. This greatly reduced the cost for the customer. The project had to interface with extensive existing software and SCADA system, and conform to all site standards and protocols while keeping downtime under approximately an hour. This was achieved successfuly, with all SCADA operators being able to view the data from the new sensors over their existing CiTect interface.

-

-