Plant Maintenance/Upgrades

-

-

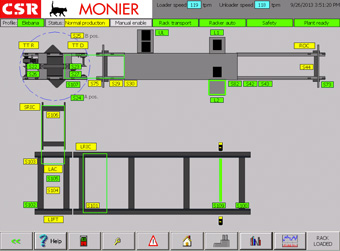

Rack Transport System Software Upgrade Jan 2015

Technologies: Advanced Software Architecture, Sequencing Operation

-

The Rack Transport system had been a long term downtime contributor for the CSR plant. Through deep analysis of the existing code it was discovered that the code was far too complex and not designed correctly. Integrelec brought forward a proposal to reprogram the entire operation of the Rack Transport System. The upgrade was to be commissioned during the christmas shutdown period resulting in a tight schedule. Integrelec completed commissioning well with the designated period and production restarted ahead of schedule.

-

-

-

-

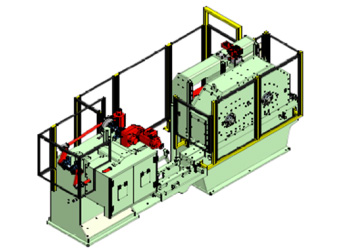

Roof Tiler Extruder Software Upgrade May 2014

Technologies: Sew Servo Motion Control, Motor Synchronisation

-

Integrelec were approached to improve the quality of the roof tile products for CSR Springvale, VIC. The root cause of the bad quality tile was the mechanical gear motor slippage which naturally occurs in many mechanical machines that have a synchronization feature of gearboxes with of unequal ratio. Using purely internal software development the entire servo code was redesigned and reprogrammed to correct this mechanical error. Over a weekend Integrelec were able to complete this upgrade with minimal disruption to the production schedule.

-

-

-

-

Dialysis Machine Sensor Changeover April 2013

Technologies: Reverse Osmosis, Hospitals

-

Integrelec was contracted to provide local Brisbane support for an OEM manufacturer based in Adelaide, since they do not have any local technicians. We were required to changeover some faulty sensors on a reverse osmosis machine used to produce ultra pure water for kidney dialysis in a hospital. Since the dialysis clinic operates more than 10 hours per day, we had to carry out the job afterhours.

Again, we integrated seamlessly into the OEM team, acting as a Freshwater System technician for the job, rather than promoting our own brand.

-

-

-

-

Food Packaging Software Upgrade Sept 2011

Technologies: PLC, Touchscreen, OMRON

-

Integrelec was contracted to provide specialist PLC programming services to an OEM equipment imported to update the functionality of two food packaging machines at and end customer’s site.

<p>While the OEM company possessed many of the required skills, they didn’t feel confident updating the PLC code itself. We integrated seamlessly into their team and provided the lacking skills.</p>

<p>At Integrelec, we are always happy to take on any part of a project that is required, and are willing to integrate in a customer team, so that the customer skills are increased and their reputation enahnced. In these situations, we will never promote our own “brand”, but instead seamless work in with the OEM machine builder’s team and brand.</p>

-

-

-

-

Potato Processing Plant Upgrade Sept 2011

Technologies: PLC, HMI, Food Industry

-

Integrelec was subcontracted by Torrens Valley Electrical to perform some upgrades to some machinery which they had previously installed at a Potato processing plant in the Lockyer Valley, Queensland. We teamed up with a local electrical contractor who knew the plant well, to add a suite of motors control valves for the new Potato and Broccoli chilling machines. Most of the programming was prepared from our Brisbane office prior to attending site, so as to keep the cost to a minimum. Ongoing support was also able to be offered after the commissioning, thanks to the remote connection that was set up, enabling us to connect directly into the PLC. Real time information could be viewed from back in our office, and small modifications and fine tuning were able to be made remotely.

-

-