What is it?

The internet of things (IoT) refers to the trend of an increasingly large number of embedded devices that are connected to the internet in some way, for the purpose of autonomously gathering and sharing information (typically without human involvement) to help with a particular task, or learn from a process.

The industrial internet of things (IIoT) refers to the extension and use of the internet of things (IoT) in industrial sectors and applications, to assist with running of plant and equipment by allowing decision making based on real-time information. IIoT is the collection of technologies that is driving Industry 4.0.

Industry 4.0 (also sometimes referred to as smart manufacturing) refers to a new phase in the Industrial Revolution that focuses on marrying physical production and operations with smart digital technology, machine learning, and big data to create a more holistic and better connected ecosystem for companies.

But with such a broad definition and even broader application, what does this mean for the average processing facility in Australia? The fact is that Industry 4.0 driven by IIoT technologies is not a single thing. It means something different to each industry and indeed each plant. For the principles to be useful they must be uniquely applied to solve specific problems.

What types of problems can it help to solve?

1. Access To Real-time information

Typically, industrial data collection has been done by connecting sensors to PLCs, and those PLCs to a historian program running on a computer onsite. This can be very effective, but suffers from a few key problems:

- High cost of initial deployment with purchase of computer hardware and historian software,

- Resources required to support and maintain the computer hardware,

- Restrictions with accessing the data. You probably need to be onsite to access it, or use remote-desktop access programs to “log-in”.

- Potential for data loss, if the onsite computer fails.

The IIoT approach to this is to move the data into shared/managed servers in the “cloud” as early in the chain as practical. The information can then theoretically be accessed from anywhere via a web browser, and the costing model moves towards a monthly subscription with lower up-front outlays.

The main up-front cost is the link between your plant PLCs and the internet, which is done by a device called an “Edge Controller”. These can take various forms from a piece of software running on an existing computer, to a dedicated piece of hardware which looks similar to a PLC. We recommend the latter because it doesn’t need onsite resources to support and is not affected by things like Operating System updates. Edge controllers typically have two isolated Ethernet connections. One links to your factory network, and the other to an internet connection (NBN, 4G etc). This keeps the factory network separate from the general internet with it’s host of security threats. It literally sits on the “edge” between your factory network and the internet.

From the Edge controller, data is passed into the cloud to a server which can record, aggregate, analyse and display it.

Integrelec has experience in installing Edge Controllers, as well as setting up web-based dashboards to display the resulting data. Please call us today to discuss how this could benefit your operations.

Examples:

Our Services

-

Solar Certification & Products

RPEQ Certification Services and ready-to-go Grid Protection/Export Control units which make the solar installer’s life easy.

-

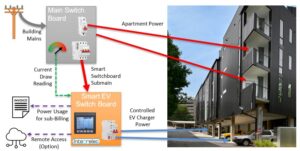

EV Readiness Assessments for Apartment Buildings

Consulting services to examine your existing electrical infrastructure and help you determine the most suitable and economical upgrades required to allow EV charging by owners and tenants.

-

Smart Switchboards for Load Management

Integrelec combines Smart Circuit Breakers with clever Load Management software to provide compact, flexible and economical power management solutions. Applications include EV charger load sharing and Peak Demand curbing.

-

Industrial Control Systems and Consultancy

We deliver the right industrial control systems for your business, including programmable logic controllers, industrial networking and human machine interfaces.

-

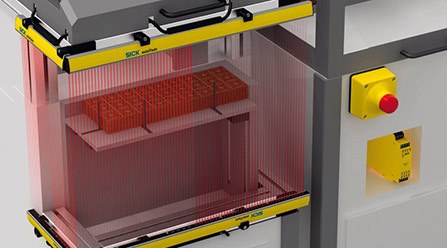

Machine Safety Systems

Safety is the top priority with everything we do. If you want a team who bring commitment to safety to your workplace, see how Integrelec can keep your machinery safe and safety compliant.

-

IoT / Industry 4.0 Solutions

Low Power Wireless Sensor Networks, Web-based Plant Dashboards, Cloud Data Analysis, plus much more. We help businesses identify and implement digitalization opportunities to improve efficiency.